The Future of Automotive Aerodynamics

It’s not incredible that so many cars look so similar. It’s incredible that cars look different at all.

By Ezra Dyer

GM

Maybe you’ve seen it: three lanes of midsize crossovers that could trade badges and nobody would notice. Those shapes are dictated by interior space, powertrain packaging, federal regulations, and production feasibility. But most of all, they’re designed for aerodynamic efficiency. When we started asking manufacturers around the country how that works, we realized that it’s not incredible that so many cars look so similar. It’s incredible that cars look different at all.

POPULAR MECHANICS

There is a basic tension between aerodynamic engineers and car designers. Each side will say that their missions are in harmony, that good design should not preclude good aerodynamics, and that aerodynamics should not limit design. But that’s not really true. The wind doesn’t care whether your grille is distinctive, or even whether you have one at all. The wind wants your car to look like a raindrop, and anything else is a compromise. Yes, every percentage of miles per gallon or range per charge matters, but visual distinction sells cars.

"LET’S WORK ON THE PART THAT NOBODY CAN SEE FIRST.”

“I always ask, ‘Have we perfected the bottom of the car?’ ” says Andrew Smith, global head of design for Cadillac. “Let’s work on the part that nobody can see first.” The aerodynamicist, then, must please both designers, like Smith, and the laws of physics, creating shapes that are visually distinctive but aerodynamically anonymous, slipping through the air with minimum drama. And this can lead to some novel solutions.

Jaguar I-Pace

JAGUAR

Consider the grille of the electric Jaguar I-Pace. Why does an electric car have a grille, an artifact of the internal-combustion engine? Standing next to a red I-Pace in the parking lot of Jaguar Land Rover’s new North American headquarters in Mahwah, New Jersey, I ask. “We’re still building our brand,” says Wayne Burgess, production studio director at Jaguar Land Rover. “All the other models have a grille, so we didn’t want to abandon that with the I-Pace. But we made it functional even though there’s no radiator behind it.”

He’s referring to how the lower half of the grille feeds air to heat exchangers for the battery’s cooling system, and the top half opens to the hood, creating a path for air to accelerate over the windshield and roof, down over the rear window to the upright tail. “You want to keep the air attached to the car, and then suddenly detach it, to minimize turbulence,” he says. “That’s why, in the plan view, looking down, the sides of the car are flat, but in profile you see curves at the tops of the fenders.” It makes sense. When it’s moving, this shape is efficient and distinct, a shark fin moving through water. But Burgess does seem a little bit wistful when he compares the I-Pace’s flat flanks to the Jaguar F-Type’s curvaceous fenders. “The F-Type has that beautiful Coke-bottle shape,” he says. “But it creates turbulence. The air gets detached.” You can’t have sexy flared fenders and low drag.

Aero R&D

A Teachable Moment Le Mans, 1999: Cresting a hill + low downforce = flight. Somehow, no one was hurt.

GETTY IMAGES

A few weeks later, I’m at GM’s Technical Center in Warren, Michigan, standing inside GM’s new wind tunnel. Nina Tortosa, the tunnel’s supervisor, fires up the 1,100-hp fan and spins the rolling road beneath a 40-percent-scale Chevy Silverado. These treadmill systems are standard now in wind tunnels because, in the real world, your car moves, but the road and air don’t. The wind tunnel must reverse both parameters or else the results will be skewed.

I always thought that wind tunnels blew smoke over cars so everyone could see how the air behaved. It turns out no one really does that. The process is messy, so it’s mainly a stunt for photos or visitors. Naturally, I want to see it. Tortosa points a wand over the top of the overgrown toy truck and smoke glides smoothly across, tracing the shape of the hood and roof before going chaotic over the bed and tailgate. She moves the wand under the truck and reveals that, yes, the exhaust system, suspension, and axles make for turbulence. It’s an empirical demonstration of why manufacturers use front air dams and even height-adjustable suspension to minimize air going under the truck. You want as much air as possible going over the smooth parts up top instead of the lumpy underbody.

GM also uses supercomputers to run elaborate fluid-dynamics simulations, the results of which guide engineers toward problem areas. “It showed a circulation bubble on the quarter-panel of the Volt,” Tortosa says. “We couldn’t see that in the tunnel.” But a wind tunnel is still essential. “Once I build a computer model, if we change something, it takes a day to run the new calculations,” says Ken Karbon, global head of simulation for aerodynamics. “Whereas, how many different iterations could you test in the tunnel?” He directs the question to Tortosa. “Thirty,” she says. “We could try 30 different things in a day.” It’s a lot of work that results in small but vital margins. “We can affect aero maybe 10 percent one way or the other—if the coefficient of drag is .30, maybe we can get it down to .27,” Karbon says. “And that might represent three-tenths of a mile per gallon in fuel economy, depending on the vehicle.”

We go next door to the center’s original wind tunnel, which is unfathomably huge. The fan looks like a propeller from the Queen Mary, fitted with six beautiful laminated spruce blades—wood is better than even carbon fiber, because if a piece of car flies off and damages a blade, technicians can easily repair it. The space is shaped roughly like an oval track, so the air circulates through the test section with the vehicle and back to the fan, requiring less power. You could host Wimbledon inside the chamber behind the fan. Seeing this stadium-size facility in person makes it obvious why not everyone has one. This is an expensive tool, a fantastic and complicated machine, so much so that no two tunnels produce the same results. “The three U.S. companies all have wind tunnels, and we all test each other’s cars,” says Tortosa. “We share the results, because each wind tunnel is different. So we like to know what our truck got in Ford’s tunnel, and vice versa.” This professional aero courtesy does not extend to foreign companies.

POPULAR MECHANICS

Technology, Not Compromise

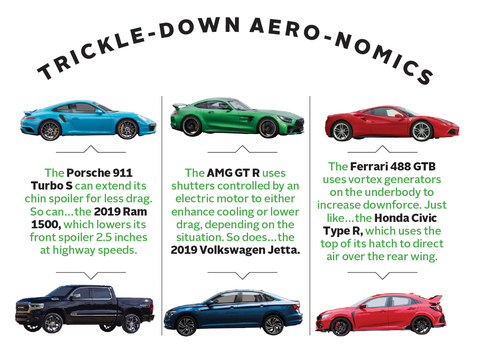

Aerodynamic principles are fixed, non-negotiable. So how will GM, Jaguar, Cadillac, and every other manufacturer continue to make cars more efficient while avoiding homogeneity? How do we get performance cars that have a high top speed (low drag) and high downforce (better handling)? One answer kept coming up: active aero, cars that don’t just passively travel through the air, but manipulate it to their benefit. This is how you resolve the compromises in performance and styling. You build a Transformer. Mercedes-AMG’s upcoming 1,000-hp supercar, the Project One, is a case in point. Before New Jersey and Michigan, I’m at the Miami International Boat Show with Gorden Wagener, chief design officer for Mercedes. Looking at a full-size clay model of the Project One, I remark on the cleanliness of its shape. “Well, there’s a lot going on under the car that you can’t see,” Wagener says. “But also, there’s active aero. There is a big wing back there, but you don’t see it when it’s parked.”

"IT DOESN’T MATTER HOW GREAT YOUR AERODYNAMICS ARE IF ONLY TEN PEOPLE BUY THE CAR."

Active aero satisfies both aerodynamicists and designers because it’s effective and mostly invisible. Lamborghini’s ALA (Aerodinamica Lamborghini Attiva) system, as deployed on the Huracán Performante, doesn’t look like much more than a wing on the rear deck. But that wing is hollow, with airflow through each of its stanchions controlled by an electric motor—and there’s a similar system in the front spoiler to balance front–rear lift. On a straightaway, the motors can channel air under the wing for low drag. Close the air intakes and the wing makes high downforce, for extra grip in corners. And the car can vary the system from side to side for “aero vectoring,” which gives even more control when steering into a corner. Now, I’ve driven the Huracán’s predecessor, the Gallardo, at 200 mph on a supersonic runway in Florida, and it was spooky, wandering and floating across the tarmac. I didn’t go that fast in the Performante, but as fast as I did go, it was glued to the road, with none of the Gallardo’s aerodynamic imbalance. Lamborghini has always prioritized top speed over handling, but active aero allows both. The Performante set a lap record at the Nürburgring, a measure of high-speed stability. But it also goes 202 mph.

Suzy Cody, GM’s head of vehicle performance for aerodynamics, says this technology is the bridge between design and engineering. “Look,” she says, “it doesn’t matter how great your aerodynamics are if only ten people buy the car. Design matters. And active aero helps enable design.” But what if, I posit, there’s a propulsion breakthrough? Right now, aerodynamics are tied to miles per gallon and electric range. What if we had batteries that were good for 600 miles of range and charged in ten minutes? Could we stop worrying about every crease in the bodywork? Could we just give those designers the flared fenders and not sweat it? In other words, would aero cease to be such a big deal? Cody, unsurprisingly, seemed aghast that I would suggest such a thing. “Even if you had a battery like that, good aero gives you other options. You could have a smaller battery, make the car cheaper, give it more passenger space, make it quieter. Aero will always be important.”

No comments:

Post a Comment