Don't Let This Mad Scratch Machine Anywhere Near Your Car

The latest from the country's dedicated test development agency

By Jacqueline Detwiler EASTMAN CHEMICAL CO./ K. IRVINE, NIST

EASTMAN CHEMICAL CO./ K. IRVINE, NISTUntil very recently, the people who need to test the scratch resistance of a car's paint had just two popular options, and both were kind of silly. The crockmeter involves moving a robotic finger over paint repeatedly, rubbing until surface scratches are created. The Amtec-Kistler car wash attacks paint with a rotating wheel of wet brushes, to simulate microscopic scratches that happen during, well, car washes.

In both cases, researchers usually create the scratches and then just kind of look at them to see how bad they are. It’s a lot like the way civilians test scratches: Stand back a couple of feet—Uh, can you see it from here?

But recently, a new way has emerged. A group of companies interested in how polymers interface with surfaces (Hyundai American, Eastman Chemical Company, and laboratory equipment maker Anton-Paar), partnered with the National Institute of Standards and Technology (NIST), for help making a better test.

NIST is a government agency that creates cool and weird tests for just about anything a company might need to standardize. (For example: They use a spark-thrower nicknamed The Dragon to test just how hard you have to try to light a roof on fire before you can call it flame-retardant). But to understand what they developed, which appeared in Progress in Organic Coatings (check that out next time you need a nap), you need a little background.

Eastman Chemical Company had been developing a new resin that could be added to automotive paint to make it more scratch-resistant. The new resin was based on an extremely tough material called TMCD that is commonly used in sport water bottles. Tests that only created surface scratches were not going to be sufficient to evaluate it. “Deep scratches caused by severe contacts (like a key, fingernails, or a shopping cart), which are big issues from appearance perspective, were ignored by tests like the crockmeter and the Amtec-Kistler,” says Eastman senior scientist Lin Feng.

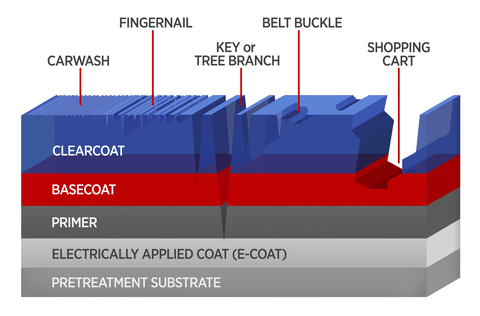

There are three stages of a car scratch—deformation, cracking, and delamination—and whether you need a new paint job depends on how far along your scratch has gone. If you only scratch the car very lightly, before the top coat (the clearcoat) cracks, you can just park your car in the sun and the heat will smooth it back out.

EASTMAN CHEMICAL COMPANY

The new test is so simple it’s hard to imagine it didn’t exist before: First, gently tap a diamond-tipped stylus across a surface to map the surface’s structure, then drag the tip across at a specific velocity and pressure to mimic scratches of different force and speed. (FYI, faster scratches are usually worse.) Finally, map the surface again to figure out what happened.

“We’ll start at one side and gradually increase the load on the way to the other side, so you can see every kind of failure that is associated with the scratch,” says Feng. Eastman, Anton-Paar, and NIST each worked on different size scales, from nanoscale scratches, which NIST performed with a diamond tip of one micron, to macroscale scratches, which Eastman performed with a tip of 200 microns and force up to 7.5 pounds.

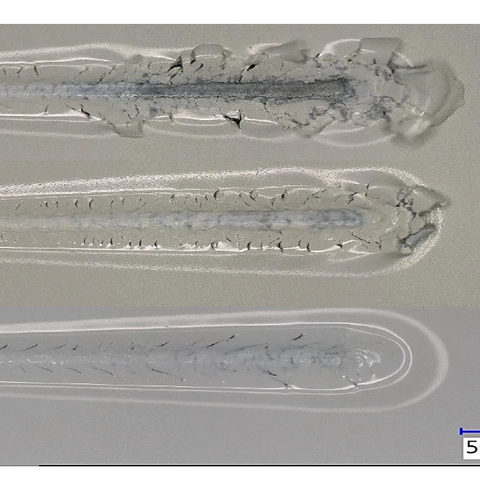

This is a photomicrograph of one of NIST’s nanoscale car scratch tests. This scratch is as deep as an average E. Coli bacterium is long.

NIST

The result: A better understanding of the precise conditions that cause your clear coat to fail—and smarter, more plastic products that make sure it won't.

No comments:

Post a Comment